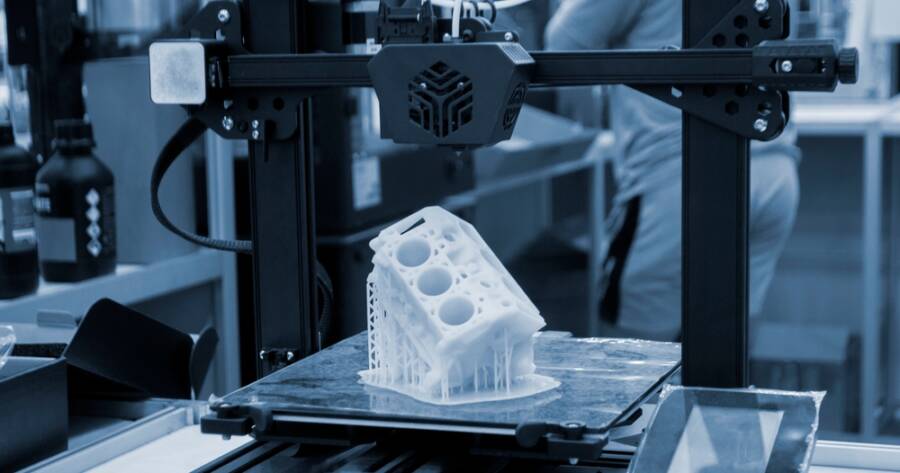

3D printing is steadily reshaping automotive manufacturing by enabling faster prototyping, reduced material waste, and highly customized components. Automakers are increasingly using additive production for lightweight parts, complex geometries, and limited-run components that traditional methods struggle to produce efficiently. As the technology matures, it promises shorter development cycles, lower costs, and greater design flexibility. Key advances are positioning 3D printing as a key driver of innovation in the next generation of vehicle production.

Faster Prototyping and Development

Car manufacturers rely on prototypes to test designs before mass production. In the past, making a prototype could take weeks or months, requiring expensive molds and tools. With 3D printing, engineers can now create prototypes in just a few hours or days. This speeds up development and allows for quick design changes.

For example, automakers like Ford and BMW use 3D printing to test new vehicle parts. Engineers can print and refine designs without waiting for costly tools to be made. This means companies can bring new models to market faster and with better performance.

Cost Savings and Less Waste

Traditional manufacturing methods, such as casting and machining, often produce a lot of waste. These processes cut away material to create a part, leading to leftover scraps. 3D printing, on the other hand, builds parts layer by layer, using only the material needed. This reduces waste and lowers material costs.

Automakers also save money on storage and transportation. Instead of keeping large inventories of spare parts, companies can 3D print them on demand. This is especially useful for rare or discontinued parts, helping car owners keep their vehicles running longer.

Lighter and More Efficient Vehicles

Lighter cars use less fuel and have better performance. 3D printing allows engineers to design parts with complex structures that are strong yet lightweight. This is important for electric vehicles (EVs), where reducing weight can extend battery life.

Companies like Bugatti and General Motors have already tested 3D-printed parts that are lighter and just as strong as traditional ones. By replacing heavy metal parts with advanced printed materials, manufacturers can improve fuel efficiency and lower emissions.

How 3D Printing Can Help Your Used Car, Too

3D printing is not only transforming new car manufacturing but also offering solutions for maintaining and restoring older vehicles. For owners of classic or discontinued models, finding replacement parts can be challenging due to scarcity or high costs. 3D printing addresses this issue by enabling the creation of precise replicas of hard-to-find components. For instance, car enthusiast Jay Leno has utilized 3D printing to reproduce parts for his vintage car collection.

By scanning existing components, even if damaged, and using computer-aided design (CAD) software, exact replicas can be printed and used to cast new parts. This approach not only preserves the authenticity of classic cars but also extends their operational life, making 3D printing a valuable tool for car enthusiasts and mechanics alike.

More Customization for Consumers

Customization is becoming more important in the car industry. With 3D printing, automakers can create unique designs without needing expensive tools. Customers can choose personalized interiors, custom trims, or even specialized performance parts.

Luxury car brands and motorsports teams are already using this technology to produce one-of-a-kind components. In the future, everyday drivers may also have the option to personalize their cars more easily. This could include everything from custom dashboards to ergonomic seats designed for individual comfort.

Challenges and Future Potential

Despite its advantages, 3D printing in car manufacturing still has limitations. The process can be slow for large-scale production, and some printed materials are not as durable as traditionally made parts. However, researchers are developing stronger and faster printing methods.

As technology advances, 3D printing could become a key part of how cars are built. Some experts even predict that in the future, entire vehicle frames could be printed in one piece, making production even more efficient.

What Else Can 3D Printing Do?

3D printing is reshaping the automotive industry, making car production faster, cheaper, and more sustainable. It allows for quick prototyping, cost savings, and greater customization.

While there are challenges to overcome, continued advancements in materials and printing speed will expand its role in manufacturing. In the coming years, this technology could lead to lighter, more efficient, and more personalized vehicles, changing how cars are made and driven.